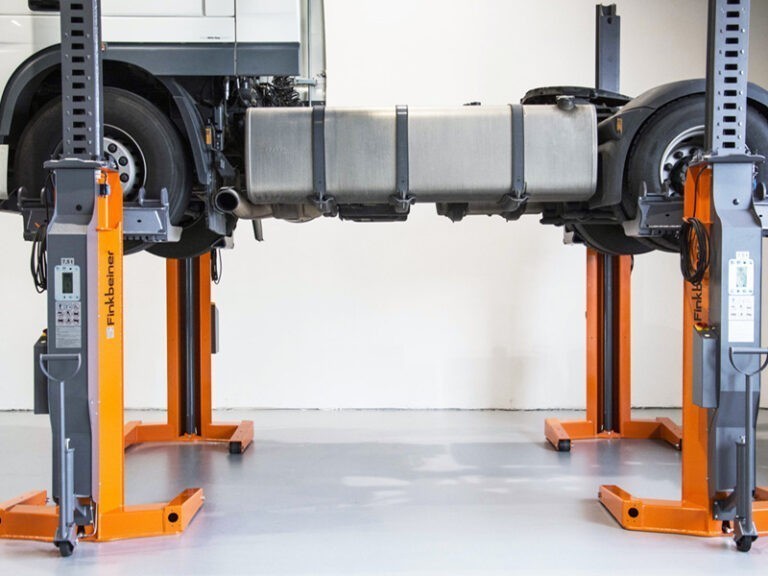

Development of an energy self-sufficient, wireless control and display system for hydraulic heavy-duty lifting applications.

Among others, the following challenges had to be considered during the development:

We developed a new control and electronics concept for our customer. As a basis for this development, we used our digital, tamper-proof data bus (CT network), which connects all participants wirelessly. The control board is based on a redundant and dual-channel microcontroller system, which uses special circuit technologies to individually monitor each wire of the wiring harness present in the system. All sensors, actuators, control panels and displays in the system are redundantly checked for functionality by the two microcontrollers and their status is published globally in the radio network. All participants communicate time-synchronously and thus monitor each other – the status of every other radio member is known to each member. This ensures the required scalable expandability of the system (including preparation for the maximum expansion stage) without follow-up costs. The data protocol is designed according to the valid safety rules. An absolute novelty is the floating master system based on our CT network. It ensures permanent functional reliability and can pass through local and global system states/measurement data from sensor to cloud (for IoT applications).

Cartesy GmbH

Am Industriepark 11

84453 Mühldorf a. Inn

Dear Sir or Madam,

we would like to thank you again this year

for your loyalty and trust!

Since we are on company vacation over the holidays, we would like to point out that no goods can be delivered during this time.

We will process incoming orders again from

January 8th, 2024.

The entire Cartesy team wishes you a Merry Christmas and a Happy New Year 2024!

on all products in the store!

Discount code: 5Winter23